- Home

- Corporate

- Projects

- Flooring Systems

- Sports Equipment

- Sports Construction Projects

- Indoor Sports Hall Construction

- Basketball Court Construction

- Volleyball Court Construction

- Athletics Track Construction

- Handball Field Construction

- Football Pitches Construction

- Indoor Astroturf Field Construction

- Children’s Playground Construction

- Tennis Court Construction

- Wire Fence Systems

- Steel Construction

- Galvanized Steel Grandstand Manufacturing

- Contact Us

- Home

- Corporate

- Projects

- Flooring Systems

- Sports Equipment

- Sports Construction Projects

- Indoor Sports Hall Construction

- Basketball Court Construction

- Volleyball Court Construction

- Athletics Track Construction

- Handball Field Construction

- Football Pitches Construction

- Indoor Astroturf Field Construction

- Children’s Playground Construction

- Tennis Court Construction

- Wire Fence Systems

- Steel Construction

- Galvanized Steel Grandstand Manufacturing

- Contact Us

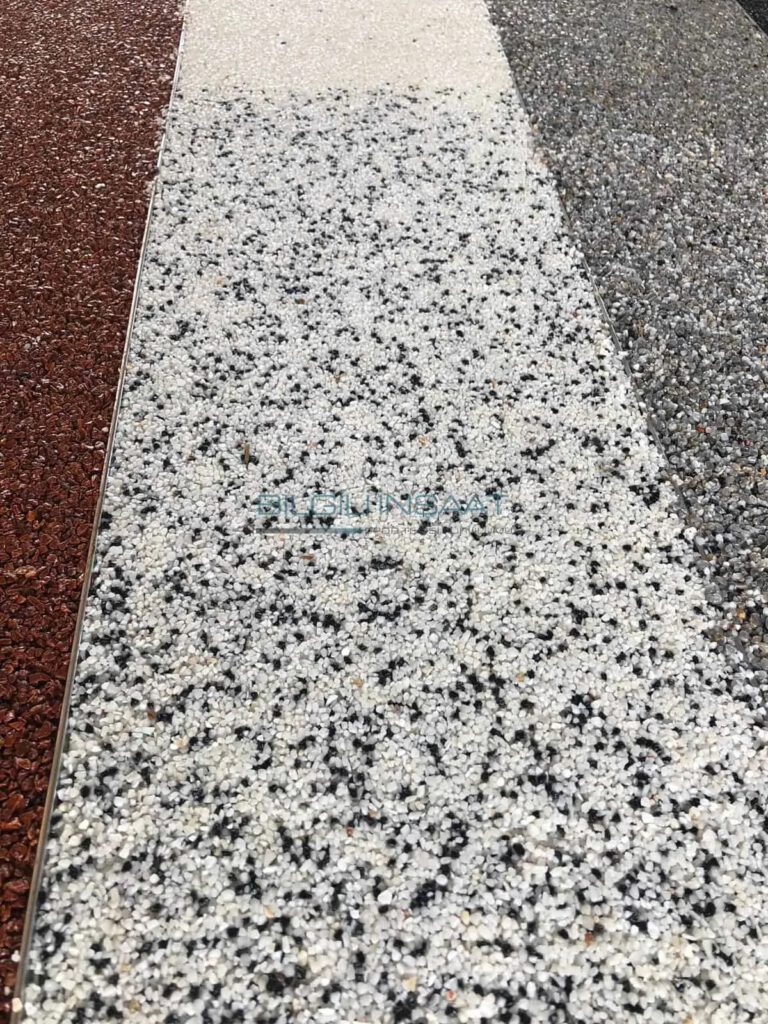

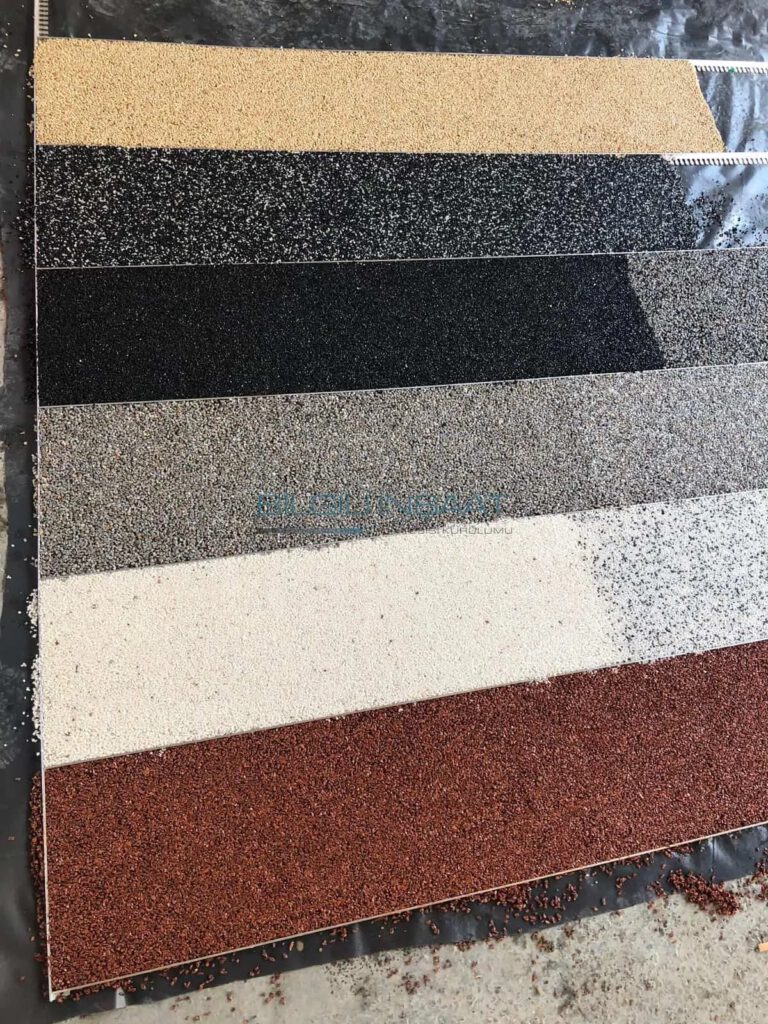

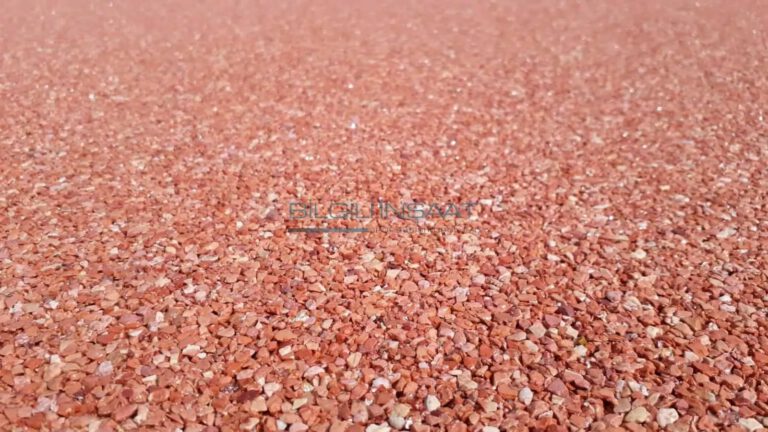

Terrazzo – Cast-in-situ Synthetic Resin Mosaic Stone

Terrazzo Flooring

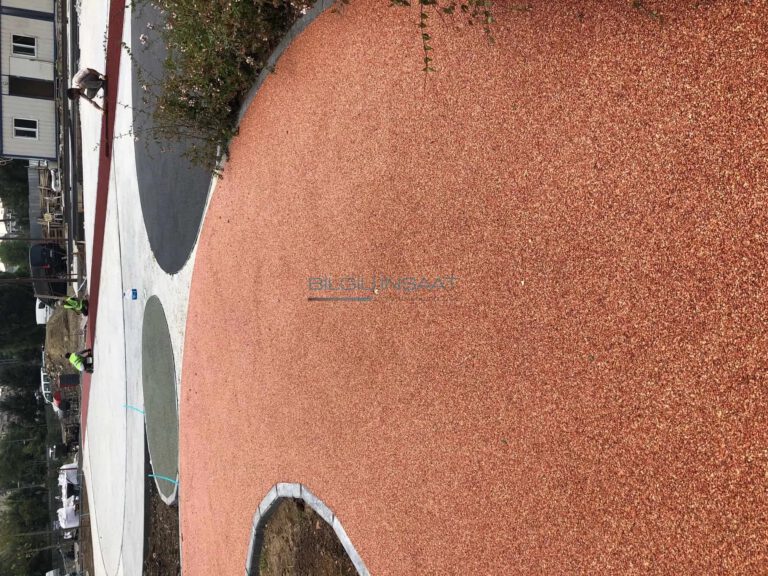

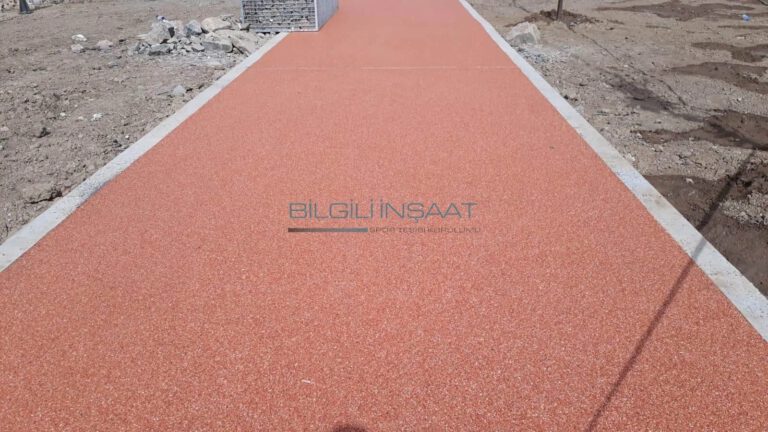

It is a decorative floor covering that is resistant to heavy pedestrian and light vehicle traffic, and can be used in outdoor and indoor areas such as walking paths, parking areas, pool edges, squares and parking areas, thanks to its water permeable and non-slip structure. It is obtained by mixing 2mm – 4mm natural aggregate and synthetic resin and then applying it to the ground in the desired thickness (minimum 8mm). Thanks to the wide color options, pattern work can be done.

Natural aggregate mixture and colorless cast-in-place synthetic resin aggregate coating flooring suitable for external conditions; It is created by preparing a mixture of binder + hardener and aggregate fractures (calibrated between 2mm-4mm) with the desired properties, and pouring it into the place determined in the project, 8 mm on pedestrian (walking) and bicycle paths, and tightening it.

Cast-in-Place Synthetic Resin Aggregate suitable for external conditions with natural aggregate mixture

Terrazzo Flooring Photos:

Other Details for Terrazzo Flooring:

- The floor C25-C30 steel mesh reinforced concrete/screed must have completed a MINIMUM 21-day curing period. If a screed is to be made, it should preferably be a reinforced screed on a reinforced concrete slab, with a minimum of 350 dosage and, if possible, fiber reinforced minimum of 5 cm. Otherwise, the CONTRACTOR will not start work until the necessary conditions are met.

- Plumbing and electrical work that must be left on the ground and completed must be completed.

- The floor should be delivered with a wooden trowel or helicopter finishing finish, with a level difference of +/-3mm.

- There should be no oil or similar stains, cracks, crusts or weak layers on the floor; if any, it should be delivered after cleaning and corrections.

- The ground is delivered/received with a ‘Site Delivery Report’ covering the above items, to be prepared jointly by the ADMINISTRATION representative and the CONTRACTOR’s site official.

- In case the ground conditions are not met, a report is taken from the ADMINISTRATION for the applications started and the application is guaranteed

- Joint slats are made with 2 mm thick aluminum L profiles. Joint laths are mechanically mounted on the floor in such a way that there are no gaps under the lath that could lead to chemical leakage.

- After the application floor is cleared of dust and dirt, Epoxy Polyurethane based primer (200gr/m2) is applied to the floor.

- Aggregate fragments are mixed homogeneously with 5% binder + hardener resin using mechanical mixers.

- The prepared mixture is poured at the desired elevation based on the elevations of the previously prepared joint slats, compacted with a trowel machine and the floor is leveled.

- It is waited for a period of time equal to the curing time recommended by the CONTRACTOR, ensuring that there is absolutely no pedestrian, bicycle or vehicle traffic on it and especially that it does not get water from anywhere. This period is between 12 hours and 24 hours, depending on weather conditions.

| PHYSICAL PROPERTIES OF THE MATERIAL | ||

| Apparent Density (kg/m3) | 2.052 ± 0.036 | TS EN 1936 |

| Actual Density (kg/m3) | 2.658 ± 0.048 | TS EN 1936 |

| Open Porosity (%) | 4.283 ± 0.469 | TS EN 1936 |

| Total Porosity (%) | 22.782 ± 0.991 | TS EN 1936 |

| Water Absorption at Atmospheric Pressure (%) | 2.080 ± 0.228 | TS EN 13755 |

| Weight Loss After Freezing-Thaw (%) | 0.748 ± 0.204 | TS EN 12371 |

| Weight Loss After Salt Crystallization (%) | 1.025 ± 0.098 | TS EN 12370 |

| MECHANICAL PROPERTIES OF THE MATERIAL | ||

| Compressive Strength (Mpa) | 12.29 ± 2.02 | TS EN 1926 |

| 1Bending Strength Under Intense Load (Mpa) | 3.77 ± 0.49 | TS EN 12372 |

| 2Bending Strength Under Intense Load (Mpa) | 2.28 ± 0.38 | TS EN 12372 |

| 3Bending Strength Under Intense Load (Mpa) | 1.44 ± 0.31 | TS EN 12372 |

| Abrasion Loss (Böhme Method) (mm | 5547 ± 943 | TS EN 14157 |

| Weight Loss After Freezing-Thaw (%) | 28.34 ± 0.06 | TS EN 14157 |

| Weight Loss After Salt Crystallization (%) | 0.2 ± 0.0 | TS 699 |

Note: The test result shown with 2 was applied to the samples after the freeze-thaw experiment, and the test result shown with 3 was applied to the samples after the salt crystallization (Sodium Sulphate) test.